Why is there Silicone Gel in Solid State Relays?

INTRODUCTION:

As a power electronic device, solid-state relays will not use or come into contact with any liquid substances in the production process, except for silicone gel. These silicone gels are inside the solid state relay and cannot be directly observed, but sometimes when the plastic packaging of the solid state relay is opened, a viscous liquid silicone gel can occasionally be found on the surface of the solid state relay (although this is rare). This article will introduce the silicone gel inside the solid state relay.

You can quickly navigate to the chapters you are interested in through the Directory below, and the Quick Navigator on the right side of the browser.

CONTENTS

1. What is the Silicone Gel? |

2. How do we use Silicone Gel? |

3. How do we clean up Silicone Gel? |

4. What are the precautions? |

1. What is the Silicone Gel?

Silicone gel is widely used in electronic components (such as precision electronic components, solid state relays, back-lights, solar energy, connectors, electrical modules, discrete devices, integrated circuit boards, etc.). Silicone gel is applied, poured or potted on electronic components to provide protection against water, moisture, gas contamination and shock absorption. Silicone gel is completely transparent when not doped with other materials, so potted electronic components can be seen directly. Even if the silicone gel is damaged, it can be repaired by re-potting, so the faulty components can be easily detected and replaced.

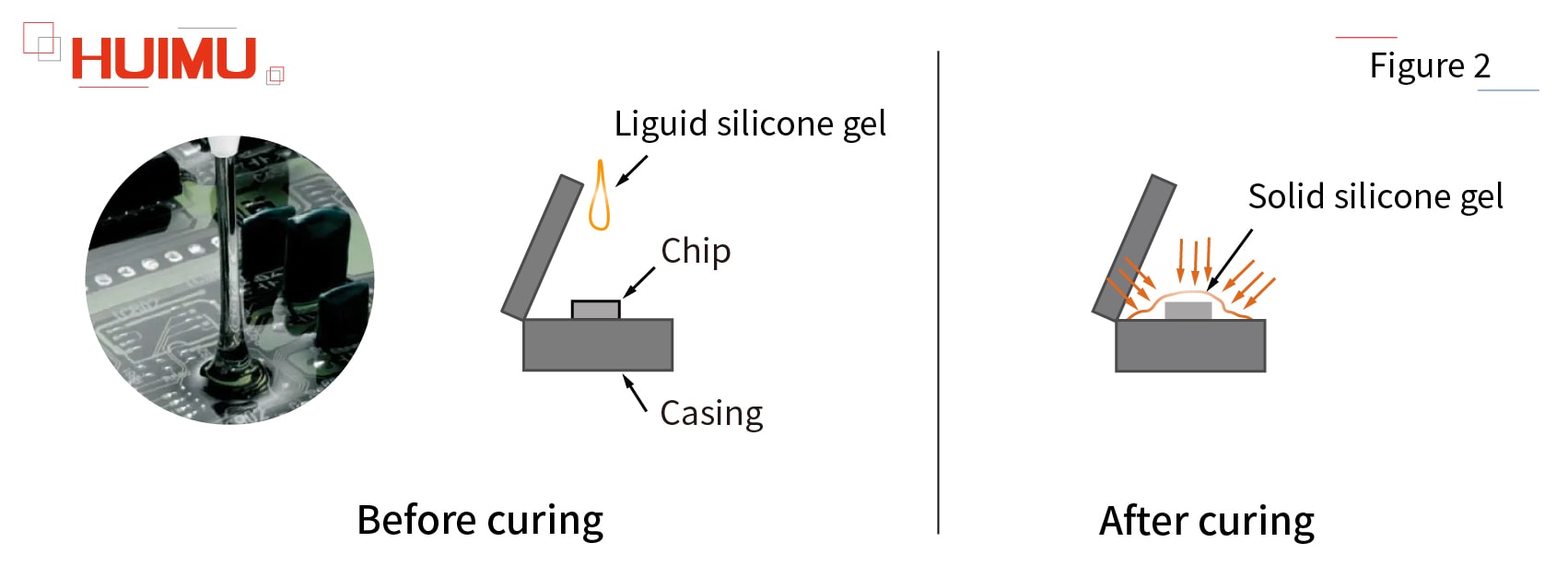

For the convenience of storage and use, the silicone gel is divided into two groups of liquid raw materials (A and B) before curing, just like AB glue. After fully mixing in a certain proportion, under the catalysis of the metal platinum complexes, the vinyl group on the silicone gel undergoes an addition reaction with the silicon hydrogen group on the cross-linking agent molecule, so that the silicone gel is easy to achieve a high degree of vulcanization. Finally, the Liquid Silicone Gel (LSG) gradually becomes a thick semi-solid elastomer. The whole reaction process does not produce by-products, so the gel body does not shrink during vulcanization.

The characteristics of silicone gel can be summarized as follows:

- It has stable physical and chemical characteristics, and can be used in a wide temperature range (-60 ℃ to 200 ℃);

- It has good electrical characteristics and weather resistance, and can be used in harsh environments such as high voltage, high temperature, and sunlight;

- It has good fluidity before curing, and can be injected into the subtleties of integrated circuit micro-components, which can effectively isolate electronic products from the external environment;

- It has a certain viscosity, and can be bonded to most materials without adding any adhesive agent or spraying adhesive on the bonding surface before curing;

- It does not contain solid fillers and is completely transparent. When it is used as a potting material, it is convenient to observe the internal structure of the potted component;

- It has good self-repair ability, and can meet the needs of the replacement of potting components and the circuit detection of metal probes;

- The gel body has good toughness and shock absorption effect after curing.

2. How do we use Silicone Gel?

The raw material A and B of liquid silicone gel are provided to us by our supplier. As long as they are mixed in a 1:1 ratio, they will solidify into a solid silicone gel after 12 hours at room temperature. Before curing, silicone gel is a colorless, odorless, non-toxic viscous liquid, we will put it to the top of the solid state relay chip during the manufacturing process. After curing, the silicone gel becomes a jelly-like elastic substance. Silicone gel has excellent insulation, ductility and thermal properties, so it can effectively protect the chip from high temperature, shock and other damage, greatly improving the service life and performance stability of the solid state relay.

3. How do we clean up excess Silicone Gel?

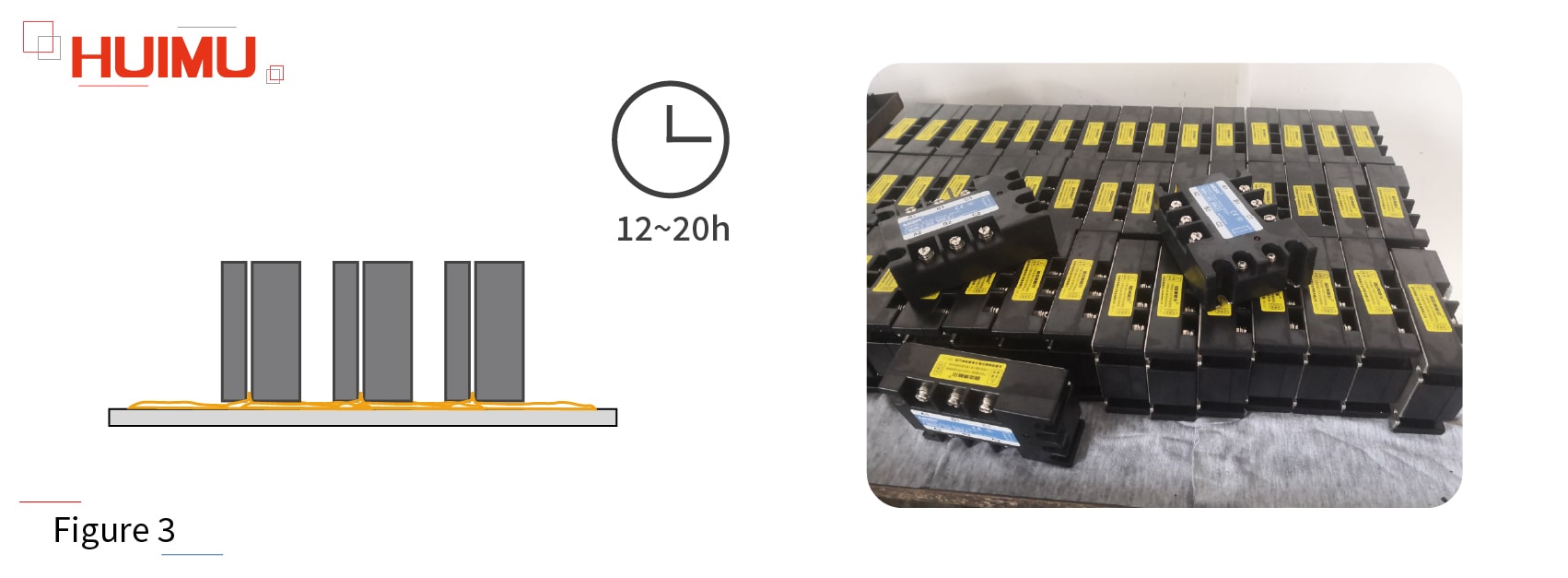

As mentioned above, sometimes some liquid silicone gel remains on the surface of the solid state relay. This is because the curing time of the silicone gel is about 12 to 20 hours (the lower the temperature, the longer the time), and if the temperature is too low or there is an error in the mixing ratio, then the excess liquid silicone gel will remain inside the solid state relay, and once they flow out, they will adhere to the surface of the solid state relay. Due to the characteristics of silicone gel, these excess silicone gels will not participate in the working process of any solid-state relay and will not produce any adverse reactions, but its slimy appearance will greatly affect the aesthetics of the solid-state relay. For this reason, we typically let solid state relays sit on their side and let them stand for several hours, allowing excess raw material and uncured liquid silicone gel to flow out. Next, we clean up these residues from the surface of solid state relays before packing them for shipping.

4. What are the precautions?

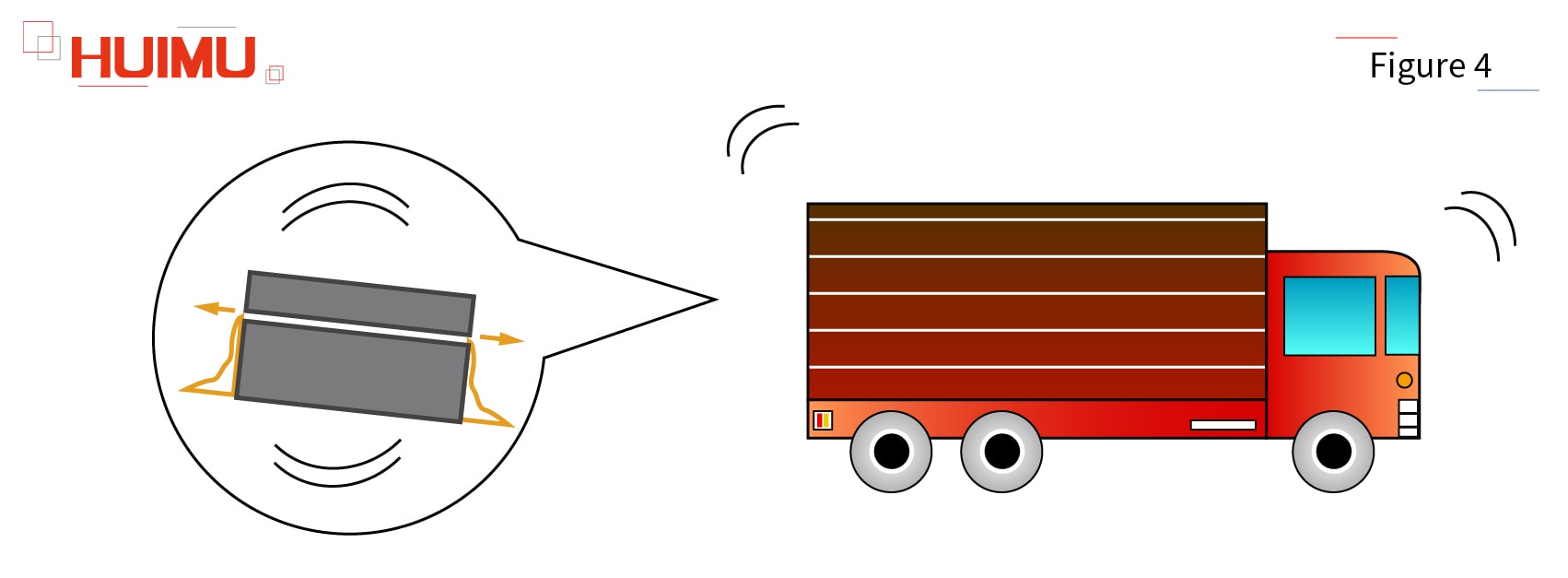

It should be noted that even if we have cleaned up most of the excess silicone gel in the solid state relay before they leaving the factory, there will still be a very small number of solid state relays that contain trace amounts of liquid silicone gel that is not fully cured, so these liquid silicone gels will flow out from the gaps in the solid state relay housing during the bumpy transportation process, thus contaminating the appearance of the solid state relay. The performance of liquid silicone gel is very stable and does not have any corrosiveness and toxicity, so if the paper or plastic packaging of the solid state relay is found to be damaged and corroded by the liquid at the time of receipt, it is likely to be caused by rain/sea corrosion. Therefore, you need to file a claim against the freight company for the fault they caused during transportation process.

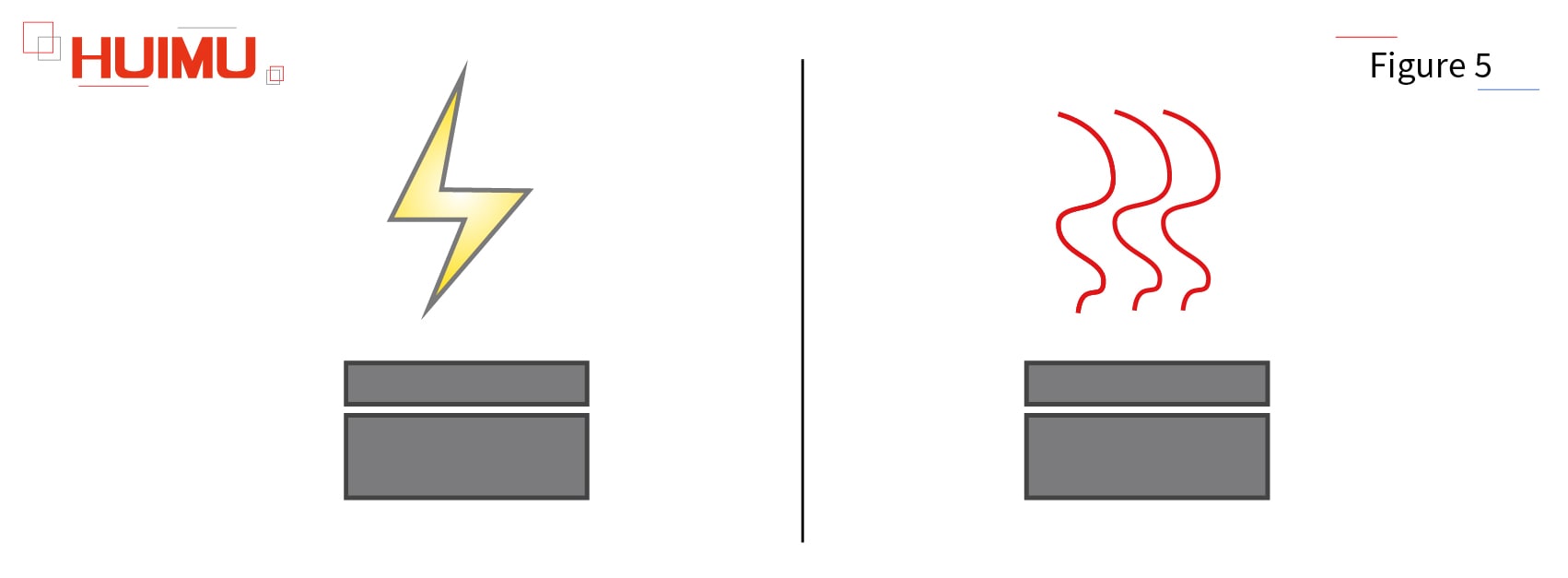

In addition, each solid-state relay must undergo a strict high-voltage withstand voltage test and high-temperature aging test before leaving the factory, and unqualified solid-state relays will be discarded. As a high-voltage-resistant, heat-insulating, non-flammable material, silicone gel will not have any adverse effects on the performance and safety of the solid state relay during the entire test process.

All in all, if you find liquid silicone gel on the surface of your solid state relay, just wipe it off.

Get in touch with us now!

Please take a minute or two to complete this simple form to get reply in 24 hours, thank you!

*Please check the trash box of your mailbox, if you do not receive our email.