What are the differences between Electromechanical Relays and Solid State Relays (EMR vs SSR)?

Nowadays, in more and more fields, traditional electromagnetic relays are being gradually replaced by solid state relays. Through this article you will learn what are the difference between EMR and SSR (EMR vs SSR)? What are the disadvantages and advantages of mechanical relay? What are the disadvantages and advantages of solid state relay? Why use solid state relays?

You can quickly navigate to the chapters you are interested in through the Directory below, and the Quick Navigator on the right side of the browser.

CONTENTS

§1. What are the Differences between EMR and SSR? |

§2. Why use Solid State Relays? |

§3. Why choose us? |

§1. What are the Differences between EMR and SSR?

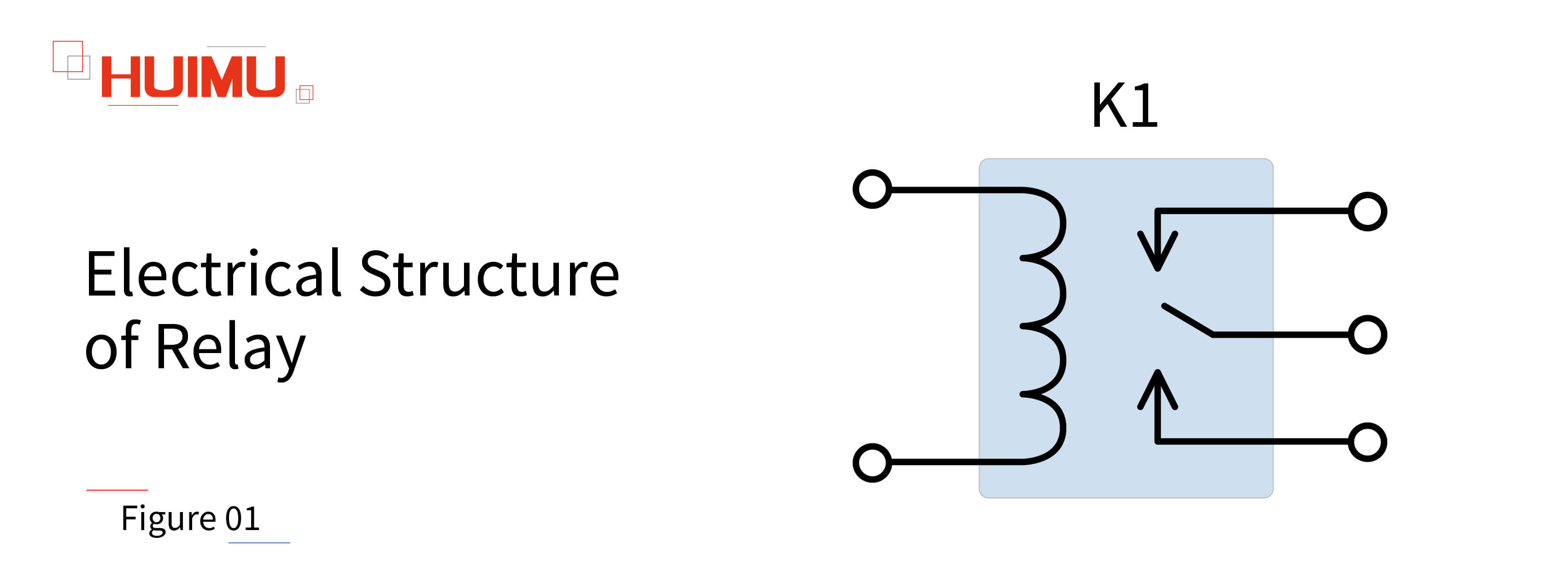

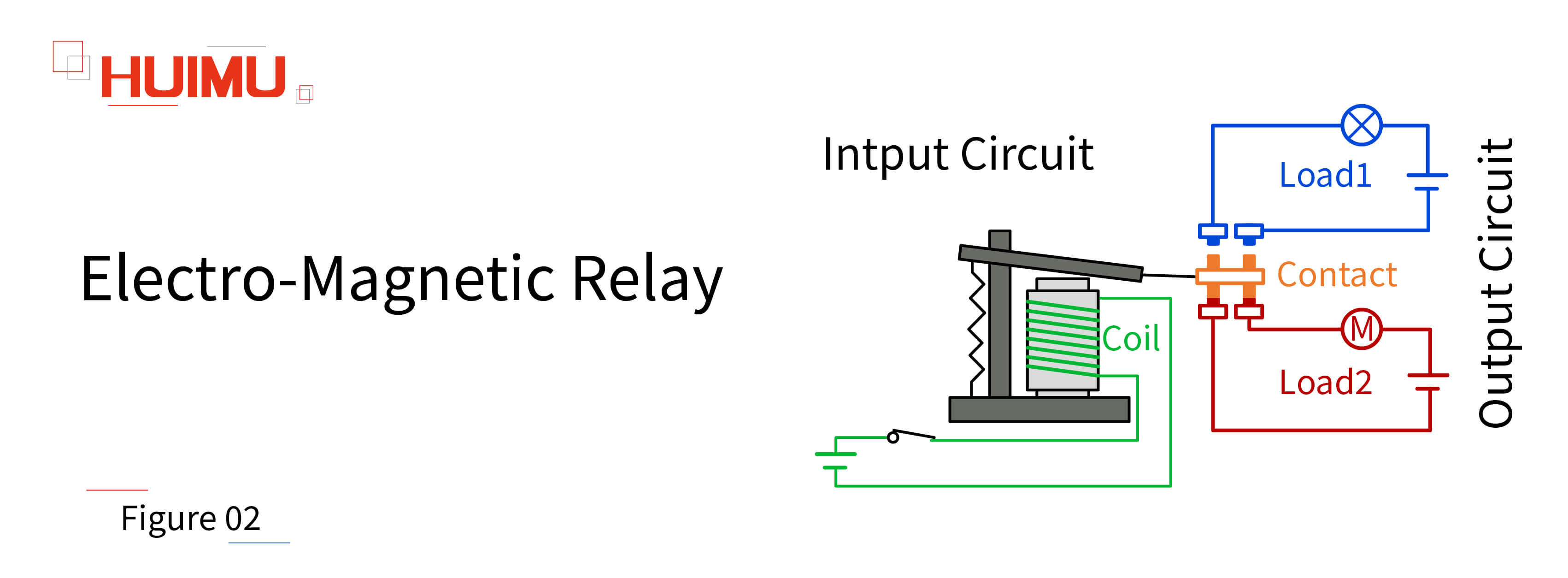

The Relay is an electronic control device that acts as an Electric Switch in almost all electrical and electronic equipment. When the input value reaches the set value, the output value will produce a step change in the output circuit, so the relays are typically used to control large output currents with low input currents. And the relays are also used for automatic adjustment (such as temperature control system), circuit protection and circuit switch.

According to the structure, the relays can be divided into mechanical relays (such as electromagnetic relay, electromechanical relay or EMR) and non-contact relays (solid state relay or SSR).

The working principle of the mechanical relay is the principle of electromagnetic induction. The structure of mechanical relay is very classic and has hardly changed since its invention, and consists of two parts: the coil and the contact.

Click here to know more information about the solid state relays

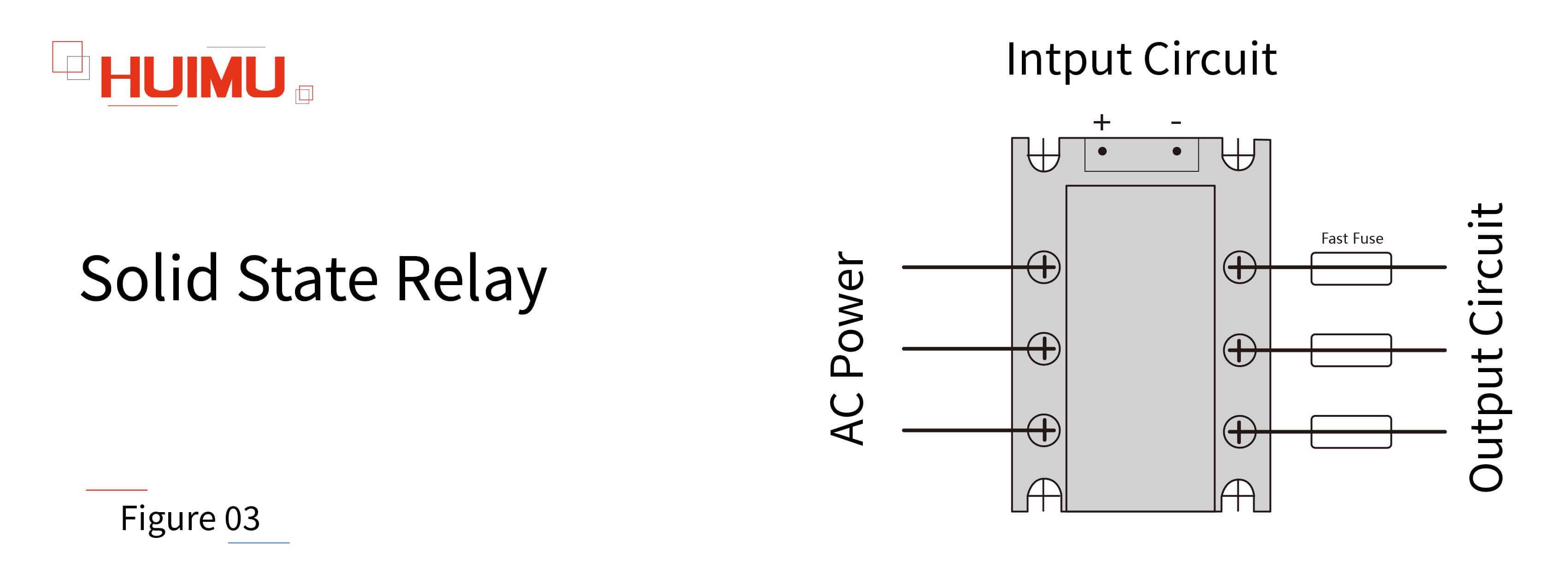

With the development of science and technology, the demand for relays (small size, long service life, high stability, high performance, and high compatibility) is increasing, so the semiconductor components are used as the switching components in the relay. There are no mechanical contact and coil in such relays, which is different with the traditional mechanical relays.

§2. Why choose Solid State Relays?

ADVANTAGES

Electromagnetic Relay | Solid State Relay |

| AC and DC compatible | Anti-vibration, anti-shock |

| Can provide multiple sets of contacts; normally open and normally closed contacts are both available | Anti-corrosion and moisture proof |

| Cheap price | Asynchronous & synchronous switching mode |

| Compact size | Compatible with digital circuits |

| Low residual voltage | Fast response time |

| No heat sink required | Low control power, usually 10-50 mW |

| No leakage current | Long life, 50-100 times longer than electromagnetic relays |

| Low electromagnetic interference(EMI) in synchronous switch mode | |

| No mechanical strain | |

| No mechanical moving parts | |

| No noisy action |

DISADVANTAGES

Electromagnetic Relay | Solid State Relay |

| Contact bounce | Leakage current |

| High control power. Usually higher than 200mW | Not suitable for small output signals |

| Limited contact life | Only a single contact |

| Maximum switching frequency is limited (5-10mhz) | Output can only be AC or DC, not compatible |

| Noisy action | Residual voltage 1-1.6V |

| Need interface for the digital loop | Usually need a heat sink |

| Poor working ability for large currents, will produce electric arc | |

| Produce electromagnetic interference (EMI) during operation | |

| Switch action cannot be fully synchronized |

The above table helps to compare the advantages and disadvantages of SSR and EMR, and it can be found that the characteristics of SSR and EMR are different due to different structures. However, in actual

application, the advantages of solid state relay are very obvious, and due to the excellent advantages as follows, which is the reason why use solid state relays, and why Solid State Relays gradually replace the Electromechanical Relays in many fields.

1- Long-life and high stability

Actually, the life of the mechanical contacts determines the life of the mechanical relay. Since there are no mechanical contacts inside the solid state relay, the service life of the SSR relays will not be shortened due to the strain, aging, corrosion, and adhesion of the contacts. At the same time, there are no mechanical moving parts (such as springs, reeds) inside the solid state relay, so contact bounce and poor contact of moving parts will not occur.

Due to the non-contact structure and the resin shell protection, the solid state relays have good impact resistance, shock resistance and corrosion resistance. Solid state relays have a wider range of applications than EMR, for examples, the humidity has little effect on the solid state relay and only slightly reduces its insulation performance, but electromagnetic relays are very sensitive to humidity, if exposed to moisture for extended periods of time, the service life of the EMR will be shortened and components will be corroded.

In summary, the life of a solid state relay is 50-100 times that of an electromagnetic relay, and the reliability of solid state relays is far superior to that of electromagnetic relays.

2- Cost of use

The initial purchase cost of solid state relays is higher than that of electromagnetic relays. But considering of other costs (like the comprehensive service life, the cost of inspection and maintenance, the loss and low efficiency due to the unstable or faulty of relays, and etc.), the average cost of using solid state relays is much lower than that of electromagnetic relays.

In addition, in some applications, additional costs are required to prevent contact vibration and poor contact of the mechanical relay.

3- Efficient control

The operating frequency (or switching rate) of solid state relays is several to several tens of times that of electromagnetic relays, which enables SSRs to be used in equipment that requires high efficiency. Moreover, solid-state relays use semiconductors as signal transmission media, so solid-state relays can be compatible with computer control systems without adding additional circuits and equipment, but EMR cannot do it.

The response time of the solid state relay is much lower than that of the mechanical relay, and the control power of the SSR relay is also lower than that of the EMR relay, which makes the EMR not applicable to equipment that requires short response time and low control power. In some special applications that requires low power factor, the switch must be stable and not subject to vibration, so EMR relays cannot be used either.

4- Electromagnetic radiation

The mechanical structure causes the mechanical relay to generate a large amount of electromagnetic interference (EMI) signals during switching period. If there is no addition protection circuit, these interference signals may adversely affect the electronic device and the power grid. And strong electromagnetic interference will even damage the human body.

In contrast, the solid state relay has good electromagnetic compatibility (EMC). And the solid state relay with zero-crossing function can reduce the influence of external interference on SSR, and also reduce the interference signal generated by the solid-state relay itself.

Therefore, if the application requires low electromagnetic interference, only solid state relays recommended.

5- More action modes

The circuit inside the solid state relay is various and can be flexibly designed according to actual needs. Through the combination of internal components, solid state relays can achieve a variety of control of the output circuit according to different state of control signals and power supplies.

However, electromagnetic relay can only switch the load asynchronously, that is to say, the state of the switch is only controlled by the control signal and is time-independent of the power signal; whereas the solid state relay can realize the control synchronously. Of course, solid state relays have more action modes, such as:

1)Asynchronous mode

2)Synchronous mode

3)Voltage zero or peak sync mode

4)Phase angle mode

5)Pulse mode

§3. Why choose us?

HUIMULTD is a company specializing in solid state relays, and supplies high-quality solid state relays and solutions to the world. Our Senior Management have collectively over 60 years` experience of production and development in Solid State Relay fields. And we are proud to offer high quality products and provide our customers with the services and support they deserve. According to customer needs, we can design solid state relays in different forms and specifications, and also provide deep OEM customized services to meet different requirements.

We strictly control the production and components of our products. Every component comes from excellent and reliable suppliers, each operation process strictly follows the IS09001 standard, and each part is rigorously tested by superb testing equipment. And products and components will be 100% tested before delivery to ensure that each manufactured product is delivered to the customer with optimal performance.

Get in touch with us now!

Please take a minute or two to complete this simple form to get reply in 24 hours, thank you!

*Please check the trash box of your mailbox, if you do not receive our email.